Image Source : shop.pall.com

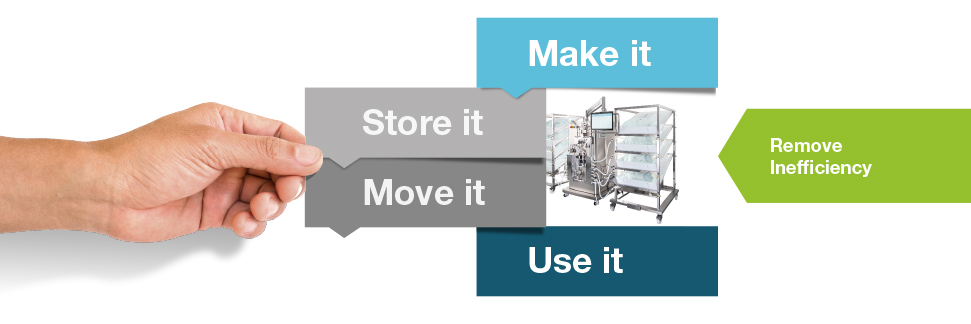

Pall Corporation extends its bioprocessing solution portfolio with the launch of three new Allegro Connect Systems. In conjunction with Pall’s Allegro® single-use portfolio, these systems deliver enhanced process and risk control, through the full automation of unit operations that combine to support the production of a wide range of therapeutic drugs and vaccines.

The rapidly growing Allegro Connect Systems portfolio now includes systems to support Depth Filtration, Virus Filtration and Bulk Fill of drug substance, and join the Buffer Management System to simplify the creation of manufacturing workflows.

Ed Hoare, Vice President and General Manager for Biotech at Pall Corporation, says: “In an increasingly dynamic bioprocessing environment, the challenge of supporting a growing variety of modalities and manufacturing workflows can easily lead to proliferation of system designs and a complex array of solutions. These can slow the specification cycle and often lead to rigid system designs that struggle to keep pace with changing process demands. Our new Allegro Connect System design combines our decades of bioprocessing knowledge with direct insights from process owners and developers to simplify those choices and deliver greater process flexibility through optimized configurability.”

The Allegro Connect Systems integrate previously manual operations, such as filter integrity testing and single-use system leak testing, reducing the need for operator intervention. With intuitive hardware, software and consumable designs, the process is simplified from installation through to batch reporting, with streamlined access to critical process data for faster, more secure batch release.

Michael Schoeb, Senior Vice President, Process Engineering, says: “Throughout the Allegro Connect range the core design DNA shines through to put the process at the heart of the design decision. This includes the elements you can see, such as the extensively tested usability features, and combines these with others that you cannot instantly see, such as new levels of automation that simplify and de-risk the way processes are run, together with novel design that maximizes product recovery for each operation.”